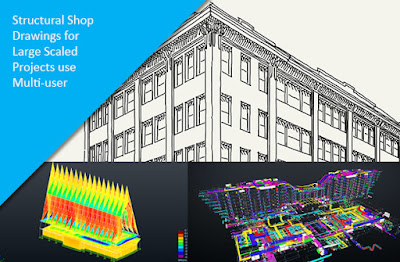

Delivering a large scaled project in smaller time frames can become impossible to achieve without the multi-user modes that the software applications provide today. Tekla is one among them that fulfil this aspect for the structural shop drawing services.

Large scaled projects require substantial resources. With the increasing complexities in design and the number of stories, the amount of planning and accuracy in detailing that would go is of vast proportions. To add to this are the stringent time-lines. Huge projects need to be delivered at unbelievable time scales. All of this has been achievable through the ever advancing technology.

Tekla is the go to software for structural detailing projects, irrespective of the scale of the project. To deliver structural shop drawing services for one of such mammoth sized projects in meagre time line is possible to fulfil with skilled and trained engineers, detailers and drafters that simultaneously work on the project. This has been doable due to the multi-user mode that the software application facilitates. It is an extremely valuable feature in situations like these.

This mode allows a number of people to add to the model at the same time. They can be located anywhere as long as they have access to the server that holds the master model. We are only dealing with this one model here. Each participant is contributing to this model saved on the server. As the user accesses this model on the server, a copy of it is saved on his system. As he works on his designated portion, it is saved on his copy. As he selects to save to the master model, his work is transferred to the master model for everyone to see.

It is essential to establish a well defined system in place for all users to comply with. This will enable smooth operation with this mode. All participants should have portions designated to them that they are to develop. This will avoid errors or rework with two users working on the same part at the same time. Also, as the mode only allows the work of only one user to be saved at a time, a proper numbering plan should be devised.

As we are dealing with only one model, the troubles of handling multiple models are completely eliminated. There is no requirement of tracking and allotting storage space to manage several models. Also, better coordination and synchronisation of work is achieved between all the project members. Confusions and conflicts rising on account of duplicate models are removed.

It is a boon for Structural shop drawing services. We have better channelisation of resources and time. Dispatch of sizeable projects in the stipulated time frame can be successfully completed.

Contact us for more details of structural steel shop drawings services.

Large scaled projects require substantial resources. With the increasing complexities in design and the number of stories, the amount of planning and accuracy in detailing that would go is of vast proportions. To add to this are the stringent time-lines. Huge projects need to be delivered at unbelievable time scales. All of this has been achievable through the ever advancing technology.

Tekla is the go to software for structural detailing projects, irrespective of the scale of the project. To deliver structural shop drawing services for one of such mammoth sized projects in meagre time line is possible to fulfil with skilled and trained engineers, detailers and drafters that simultaneously work on the project. This has been doable due to the multi-user mode that the software application facilitates. It is an extremely valuable feature in situations like these.

This mode allows a number of people to add to the model at the same time. They can be located anywhere as long as they have access to the server that holds the master model. We are only dealing with this one model here. Each participant is contributing to this model saved on the server. As the user accesses this model on the server, a copy of it is saved on his system. As he works on his designated portion, it is saved on his copy. As he selects to save to the master model, his work is transferred to the master model for everyone to see.

It is essential to establish a well defined system in place for all users to comply with. This will enable smooth operation with this mode. All participants should have portions designated to them that they are to develop. This will avoid errors or rework with two users working on the same part at the same time. Also, as the mode only allows the work of only one user to be saved at a time, a proper numbering plan should be devised.

As we are dealing with only one model, the troubles of handling multiple models are completely eliminated. There is no requirement of tracking and allotting storage space to manage several models. Also, better coordination and synchronisation of work is achieved between all the project members. Confusions and conflicts rising on account of duplicate models are removed.

It is a boon for Structural shop drawing services. We have better channelisation of resources and time. Dispatch of sizeable projects in the stipulated time frame can be successfully completed.

Contact us for more details of structural steel shop drawings services.

Comments

Post a Comment